In the world of laser drilling, precision and accuracy are of utmost importance. Manufacturers and engineers constantly strive for perfection when it comes to creating intricate holes in a variety of materials. This is where control cards play a vital role in achieving programming perfection. In this blog, we will explore the significance of control cards in laser drilling innovation and how they contribute to the success of the process.

The Basics of Laser Drilling

Laser drilling is a technique that involves using a high-energy laser beam to create holes in materials like metals, plastics, ceramics, and even diamonds. This process offers several advantages over traditional drilling methods, such as greater precision, higher productivity, and the ability to create complex patterns. However, to achieve optimal results, the laser drilling process relies heavily on control cards.

What is a Laser Control Card?

A laser control card is an essential component of any laser drilling system. It acts as the brain that controls the movement and intensity of the laser beam, ensuring it accurately follows the predetermined patterns and parameters. These control cards are typically programmed using specialized software that allows engineers to input the desired specifications for each drilling operation.

The Importance of Control Cards in Programming Precision

Control cards play a crucial role in achieving programming perfection in laser drilling. They enable engineers to precisely control the laser's power, pulse duration, beam alignment, and other critical factors that determine the quality of the drilled holes. By programming the control card with the right parameters, manufacturers can ensure consistent and accurate drilling results, even in complex applications.

Advancements in Laser Control Card Technology

Over the years, control card technology has witnessed significant advancements, further enhancing the capabilities of laser drilling systems. Modern control cards integrate advanced algorithms and sensors that enable real-time monitoring and adjustment of drilling parameters. This allows for improved control, higher drilling speeds, and reduced downtime. Additionally, advanced control cards offer compatibility with various laser types, making them versatile and adaptable to different drilling requirements.

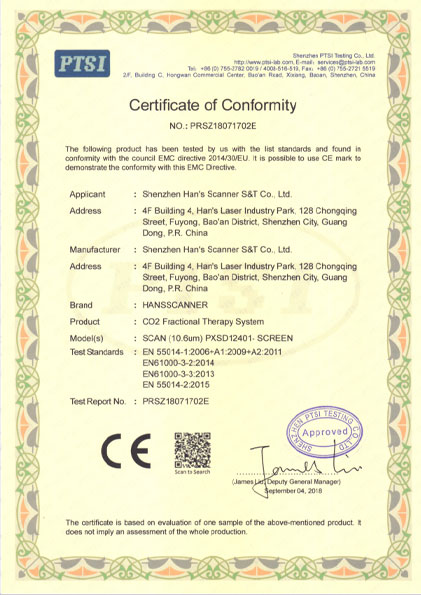

In conclusion, control cards play a pivotal role in achieving programming perfection in laser drilling. The precise control they offer over laser parameters ensures accurate and consistent results, enabling manufacturers to create intricate patterns and holes with utmost precision. As technology continues to advance, the capabilities of control cards will only expand, further revolutionizing the field of laser drilling. So, the next time you witness a perfectly drilled hole, remember that behind its perfection lies the exceptional control of a laser control card from brands like Hansscanner.

zh-CN

zh-CN

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt