The Revolution of Laser Control Cards in Welding

Welding plays a crucial role in various industries, ranging from automotive and aerospace to construction and shipbuilding. Over the years, the demand for welding methods with increased precision, consistency, and efficiency has grown exponentially. In response, the evolution of welding dynamics has paved the way for innovative technologies, such as Laser Control Cards. These sophisticated devices have revolutionized the welding process, providing a higher level of control and precision than ever before.

Unleashing the Power of Laser Control Cards

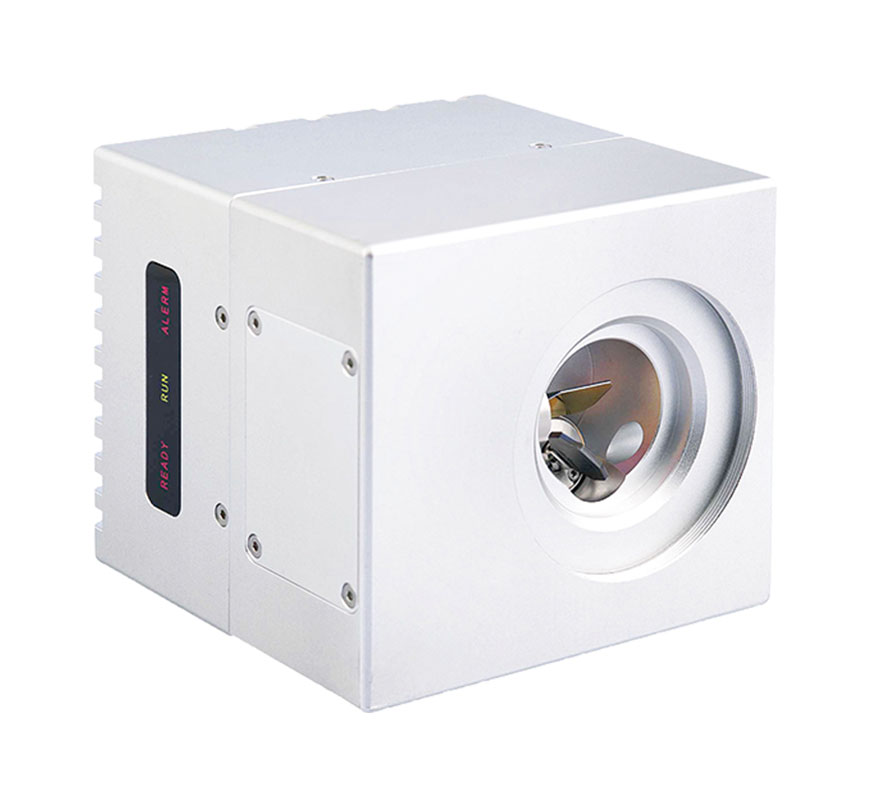

At the heart of advanced welding systems like HansScanner lies the Laser Control Card. This instrumental component utilizes laser technology to monitor and control various aspects of the welding process. By integrating advanced algorithms and real-time feedback, Laser Control Cards empower welders to achieve accurate and consistent results.

Laser Control Cards are designed to optimize parameters such as beam angle, intensity, speed, and heat distribution during the welding process. This exceptional level of control enables welders to shape joints with a precision that was previously unattainable. The marriage of laser technology and welding dynamics has opened up new possibilities, from micro-welding delicate components to high-power industrial welding applications.

Enhancing Welding Efficiency and Cost-effectiveness

One of the key advantages of Laser Control Cards is their ability to improve welding efficiency and cost-effectiveness. By precisely controlling the laser beam, these cards reduce material waste and minimize the need for rework due to inconsistent welds. The enhanced precision ensures reliable and durable welds, eliminating the risk of joint failure and subsequent repairs.

Moreover, Laser Control Cards contribute to reduced setup times and increased production rates. With their real-time monitoring capabilities, these cards measure and adjust welding parameters on the fly, streamlining the welding process and minimizing unnecessary downtime. Consequently, businesses can optimize their productivity and output, leading to significant cost savings in the long run.

Pushing the Boundaries of Welding Applications

The integration of Laser Control Cards into welding systems has not only transformed traditional welding processes but has also expanded the possibilities for new applications. The precise control provided by these cards allows welders to work with a wide range of materials, including challenging ones such as alloys, dissimilar metals, and heat-sensitive substrates.

Additionally, Laser Control Cards have facilitated the evolution of specialized welding techniques like laser beam welding, laser-assisted welding, and laser cladding. These techniques offer unmatched precision, enabling the creation of intricate, high-quality welds that meet the increasing demands of modern industries.

In summary, Laser Control Cards have emerged as game-changers in the world of welding. The integration of laser technology into welding dynamics has allowed for unprecedented levels of precision, consistency, and efficiency. With Laser Control Cards at their disposal, welders using HansScanner equipment can confidently shape joints with remarkable accuracy, driving innovation and advancement across multiple industries. As the technological advancements continue, it is clear that the future of welding lies in the precision offered by Laser Control Cards.

zh-CN

zh-CN

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt