In the ever-evolving field of micromachining, the demand for high precision and efficiency continues to drive innovation. One such innovation that has been revolutionizing the industry is the use of fiber laser lens technology. With its ability to produce precise and powerful laser beams, fiber laser lenses have opened up new possibilities in micromachining applications. In this blog post, we will explore the benefits and applications of fiber laser lenses in micromachining.

What are Fiber Laser Lenses?

Fiber laser lenses are a crucial component in fiber laser systems used for micromachining. These lenses are designed to focus and shape laser beams, allowing for precise control and manipulation of the laser energy. Made from high-quality materials such as fused silica or sapphire, fiber laser lenses are known for their high transmission efficiency and excellent thermal stability.

Advantages of Fiber Laser Lenses in Micromachining

Fiber laser lenses offer several key advantages that make them well-suited for micromachining applications:

High Precision

Fiber laser lenses provide exceptional focusing capabilities, allowing for precise control over the laser beam spot size. This level of precision is critical when working on delicate and intricate microstructures.

High Power Density

Fiber lasers can generate high-power beams with intense power densities. The use of fiber laser lenses ensures that this concentrated energy is properly focused and delivered to the workpiece, resulting in efficient material removal and improved processing speed.

Versatility

Fiber laser lenses can be designed to fit a wide range of laser systems and operating parameters. This versatility allows for customization and optimization based on specific micromachining requirements, ensuring the best possible performance and results.

Long Lifespan

Fiber laser lenses are built to withstand intense laser radiation and high thermal loads. Their robust design ensures a long lifespan, reducing the need for frequent replacement and maintenance, saving time and costs in the long run.

Applications of Fiber Laser Lenses in Micromachining

Fiber laser lenses find applications across various micromachining fields, including:

Precision Cutting

Fiber laser lenses enable precise cutting of intricate patterns and features in materials such as metals, ceramics, and polymers. From medical devices to electronics components, fiber laser lenses play a crucial role in achieving high-quality cuts with minimal heat-affected zones.

Microdrilling

With their ability to focus laser energy into a small spot, fiber laser lenses are ideal for microdrilling applications. Whether it's creating microvias in circuit boards or manufacturing micron-scale nozzles, fiber laser lenses ensure accuracy and repeatability in microdrilling processes.

Surface Texturing

Fiber laser lenses can be used to create intricate surface textures on various materials.

Microengraving

Fiber laser lenses enable the precise engraving of small details and patterns on a wide range of materials, including metals, plastics, and glass.

Choosing the Right Fiber Laser Lens

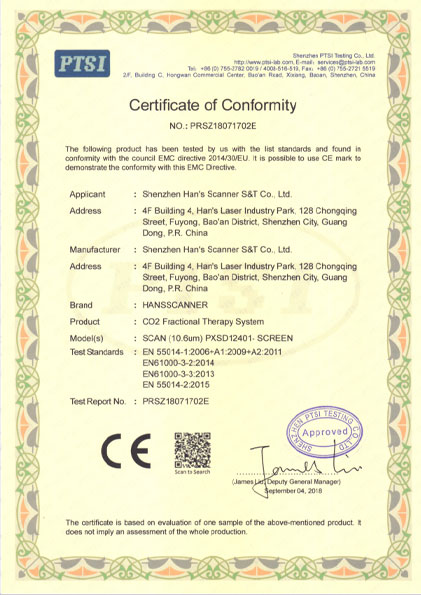

When selecting a fiber laser lens for micromachining, factors such as wavelength compatibility, beam diameter, working distance, and lens material must be considered. Brands like Hansscanner offer a wide range of high-quality fiber laser lenses designed specifically for micromachining applications. It is essential to choose a lens that is compatible with your laser system and can deliver the desired level of precision and performance.

Fiber laser lenses have undoubtedly revolutionized the field of micromachining. Their ability to produce precise, powerful, and customizable laser beams has opened up new possibilities in various applications. Whether it's cutting, drilling, engraving, or surface texturing, fiber laser lenses offer the precision and efficiency required for high-quality micromachining processes. Brands like Hansscanner provide advanced fiber laser lens options that are built to deliver exceptional performance and longevity in the micromachining industry.

zh-CN

zh-CN

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt