Laser scanning galvanometers and lasers are traditionally mainly used in fields such as marking and rapid prototyping. Such systems provide high-quality beams, but the laser power is limited to the 100-watt range. Today, with the advent of high-brightness lasers such as fiber lasers, disk lasers, and even some lower-brightness high-power diode lasers, the application field of scanning galvanometers has expanded to several kilowatts. The scanning unit must be able to handle applications in the high power range - without compromising accuracy and speed! This is a challenging task for galvanometer manufacturers.

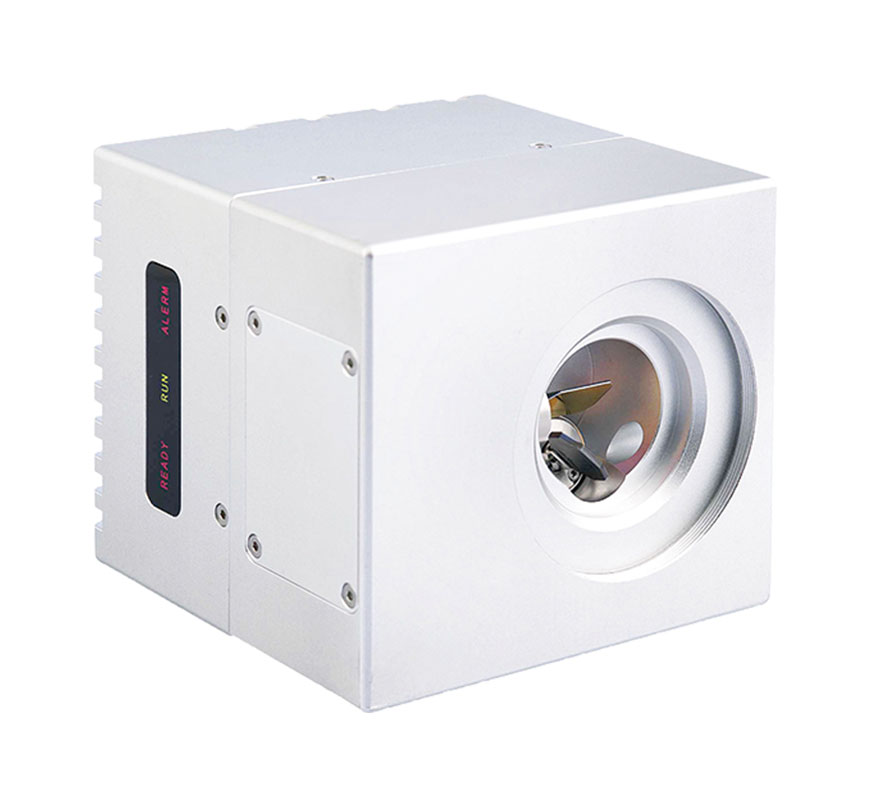

A basic xy scanning setup looks simple: two mirrors, driven by motors, reflect an incoming laser beam to any point in a specific area. A set of flat field lenses ensures that the focal point is in the plane of the working area. For basic lasers, the typical working range is 40 x 40 mm2 to 180 x 180 mm2; for advanced harmonic lasers and diode lasers, the working range is 40×40 mm2 to 120×120 mm2, depending on the focal length of the plan lens. Obviously, the larger the required working range, the longer the working distance. If a combination of a focusing lens and a movable lens is used to replace the flat-field lens in the laser light path at the front of the scanning galvanometer, the working range and working distance will be further increased.

Laser scanning galvanometer 3D printing is based on mathematical modeling model documents, using special wax materials, powdered metals or plastics and other bondable raw materials, and the technical application of structural blocks according to the method of step-by-step printing and bonding. It is completely different from the traditional raw material production and processing.

The laser scanner galvanometer 3D printer is a symbol of high-precision and high-speed desktop laser scanning galvanometer 3D printers. It solidifies rapidly under scanning irradiation, and can directly obtain resin or products similar to engineering plastics. With the rapid development trend of the application of 3D printing technology, with the advantages of speed and precision, laser technology as a new energy source is widely used in 3D printing, in which the selective solidification process of photosensitive resin occupies a dominant position in the market.

By improving accuracy, speed and laser power, galvanometers have become a very important tool in laser processing. Its market has expanded from traditional marking and rapid prototyping applications to laser material processing in multiple areas, including cutting, welding, surface treatment, polymer welding and other applications. Galvo technology and innovative mechatronic design concepts, especially new materials and smart solutions for mirror technology, have adapted to new market requirements. High-brightness laser sources open up a bright future for galvanometers.