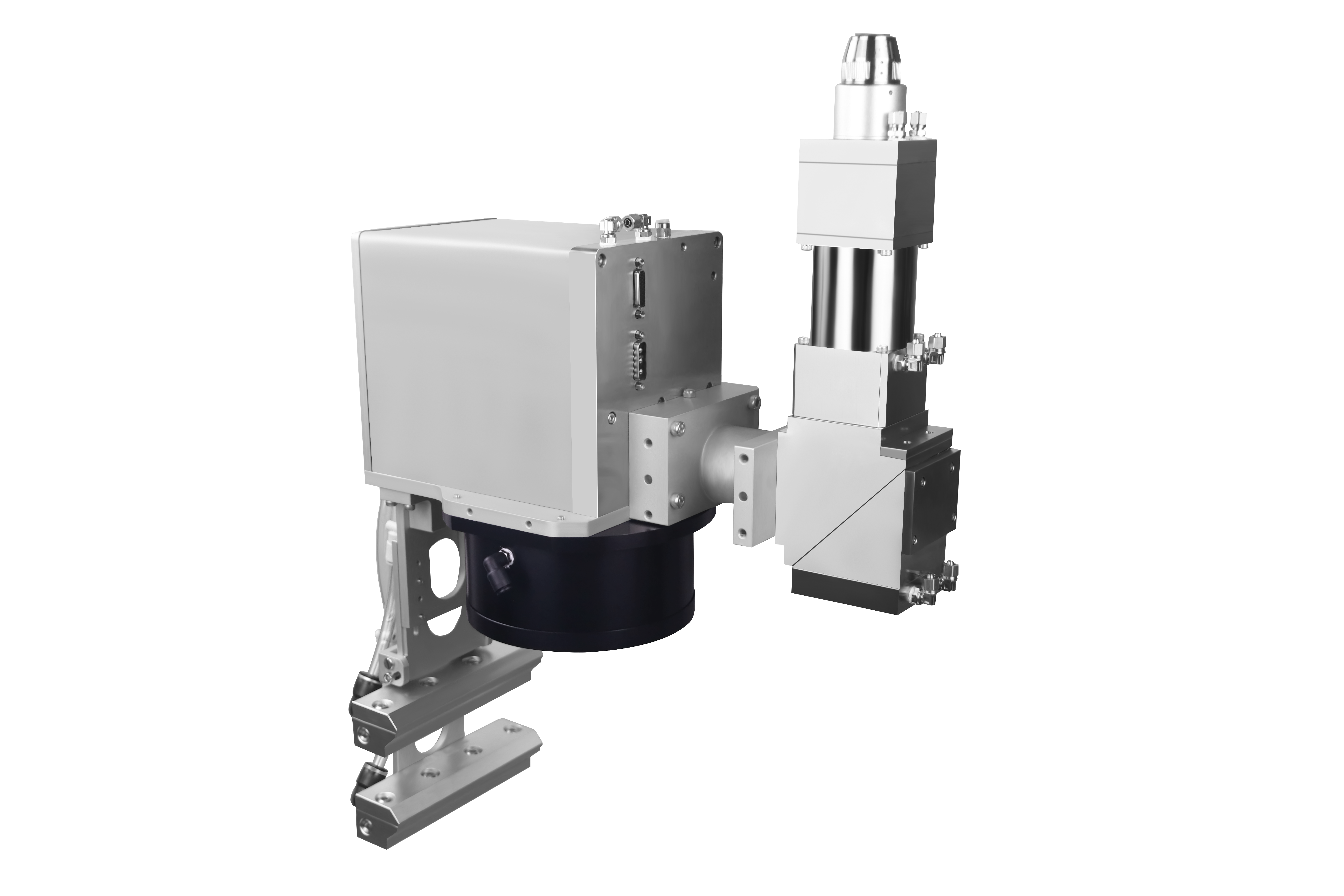

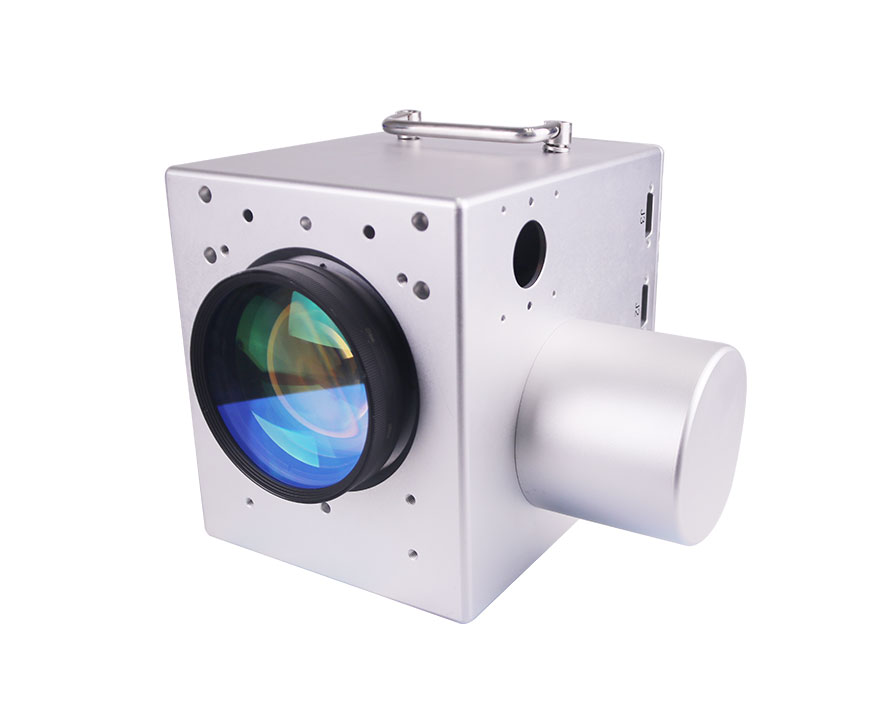

High power galvo laser welding system is independently developed by Scanner Optics. The system after fully validated, with carefully designed double wind cooling water circulation system and excellent whole sealing, strict selection and testing of optical element, the assembly process, can be in 6KW laser power work stably for a long time. High power laser welding system consists of high power galvanometer and control cabinet. The high power galvanometer system consists of a galvanometer, collimation, connection, red light indicator system and auxiliary accessories. Now it is mainly used in lithium battery welding industry, automobile welding, consumer electronics, hardware processing, aerospace and other industries.

zh-CN

zh-CN

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt