When it comes to laser scanning systems, the f-theta lens design plays a crucial role in achieving precision and accuracy. This lens design is specifically developed for laser scanning applications, ensuring a constant scanning speed and accurate positioning over the entire scanning area. Over the years, significant advancements have been made in the materials used for f-theta lens design, enhancing the performance and versatility of laser scanning systems. In this blog, we will explore some of these materials and how they have revolutionized f-theta lens design.

High-Transmittance Optical Materials

One of the key requirements for an f-theta lens is its ability to transmit the laser beam efficiently. High-transmittance optical materials, such as fused silica and synthetic crystals like CaF2, have become popular choices due to their excellent optical properties. These materials offer low absorption, high transmittance, and minimal dispersion, ensuring minimal energy loss and delivering high-quality scanning results.

Low Dispersion Materials

Dispersion is an optical phenomenon where different colors of light travel at different speeds through a material, causing chromatic aberration. In f-theta lens design, chromatic aberration can result in image distortion and reduced scanning accuracy. To overcome this, the use of low dispersion materials, such as fluorite and extra-low dispersion (ED) glass, has become prevalent. These materials have a minimized dispersion range, leading to sharper and more accurate laser beams.

Thermal Stability Materials

The heat generated during laser scanning can cause the f-theta lens to expand or distort, leading to compromised performance. To address this challenge, thermal stability materials like calcium fluoride (CaF2) and silicon have been introduced. These materials have excellent thermal conductivity and low coefficient of thermal expansion, enabling them to withstand high temperatures without significant changes in shape or optical properties. The incorporation of thermal stability materials improves the reliability and longevity of f-theta lenses.

New Coating Technologies

To optimize the performance of f-theta lenses, advanced coating technologies have been developed. Anti-reflective (AR) coatings are applied to lens surfaces to minimize reflection losses and increase light transmission. Additionally, coatings that offer high damage threshold have been introduced to protect the lens from laser-induced damage. These new coating technologies enhance the optical efficiency, durability, and overall performance of f-theta lenses.

In conclusion, the advances in materials used for f-theta lens design have revolutionized the field of laser scanning systems. High-transmittance optical materials like fused silica and CaF2, low dispersion materials such as fluorite and ED glass, and thermal stability materials like CaF2 and silicon have vastly improved the performance, precision, and durability of f-theta lenses. Furthermore, the introduction of new coating technologies has enhanced the optical efficiency and longevity of these lenses. As technology continues to evolve, we can expect even more exciting developments in f-theta lens design, further pushing the boundaries of laser scanning systems.

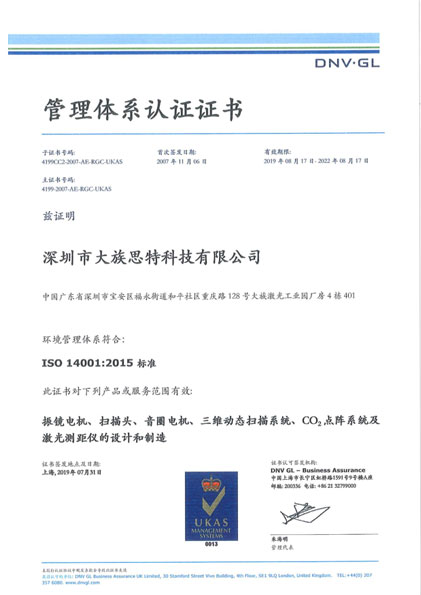

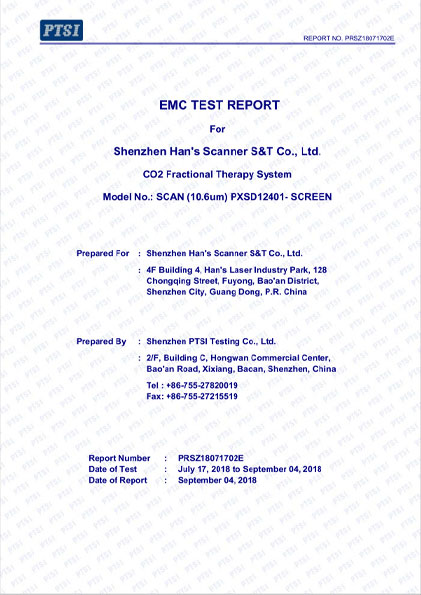

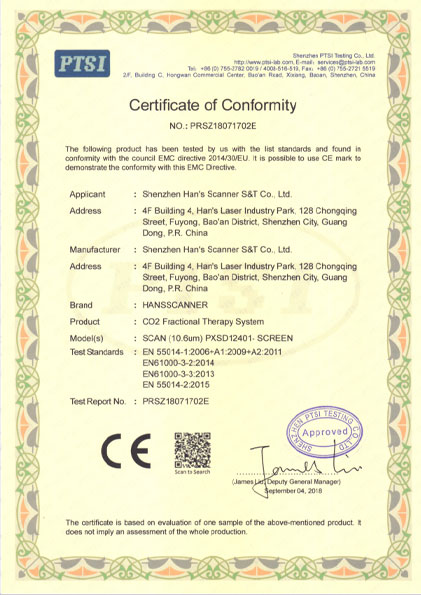

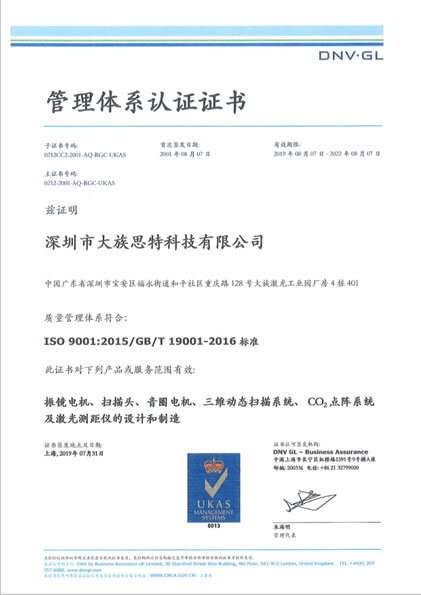

When it comes to choosing a brand that excels in f-theta lens design, Hansscanner stands out as a reliable and innovative manufacturer. With their expertise and commitment to quality, their f-theta lenses deliver exceptional performance in laser scanning applications. Whether you need precise marking, cutting, or imaging, Hansscanner's f-theta lenses are designed to meet the highest standards of accuracy and reliability.

zh-CN

zh-CN

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt