Laser Software Function

SkyWriting Function

SkyWriting is an intelligent trajectory optimization technology developed to enhance the quality of laser marking software and engraving software tasks. It uses advanced algorithms to control laser switching timing and scanning speed in real time, effectively preventing corner overburning in complex laser cutting design software applications and ensuring consistent surface quality.

Signal Trigger Marking

Users can pre-bind the preset marking document to the device-specific input (IO) interface. When triggered by an external PLC system, the laser control software automatically executes the stored laser marking software task, ensuring precise and efficient processing for industrial applications.

Multi-Document Marking

The multi-document loop marking function is an ideal choice for production lines, assembly line operations, or those that require frequent switching of marking content. It minimizes operator intervention through automated task switching and queue cycle management, ensuring efficient, smooth and uninterrupted continuous marking operations. It is particularly suitable for production lines that require high-rhythm and repetitive marking tasks, such as mixed-flow production of multiple product models, cyclic marking of fixed serial

numbers/batch numbers, and alternating marking of various patterns or logos.

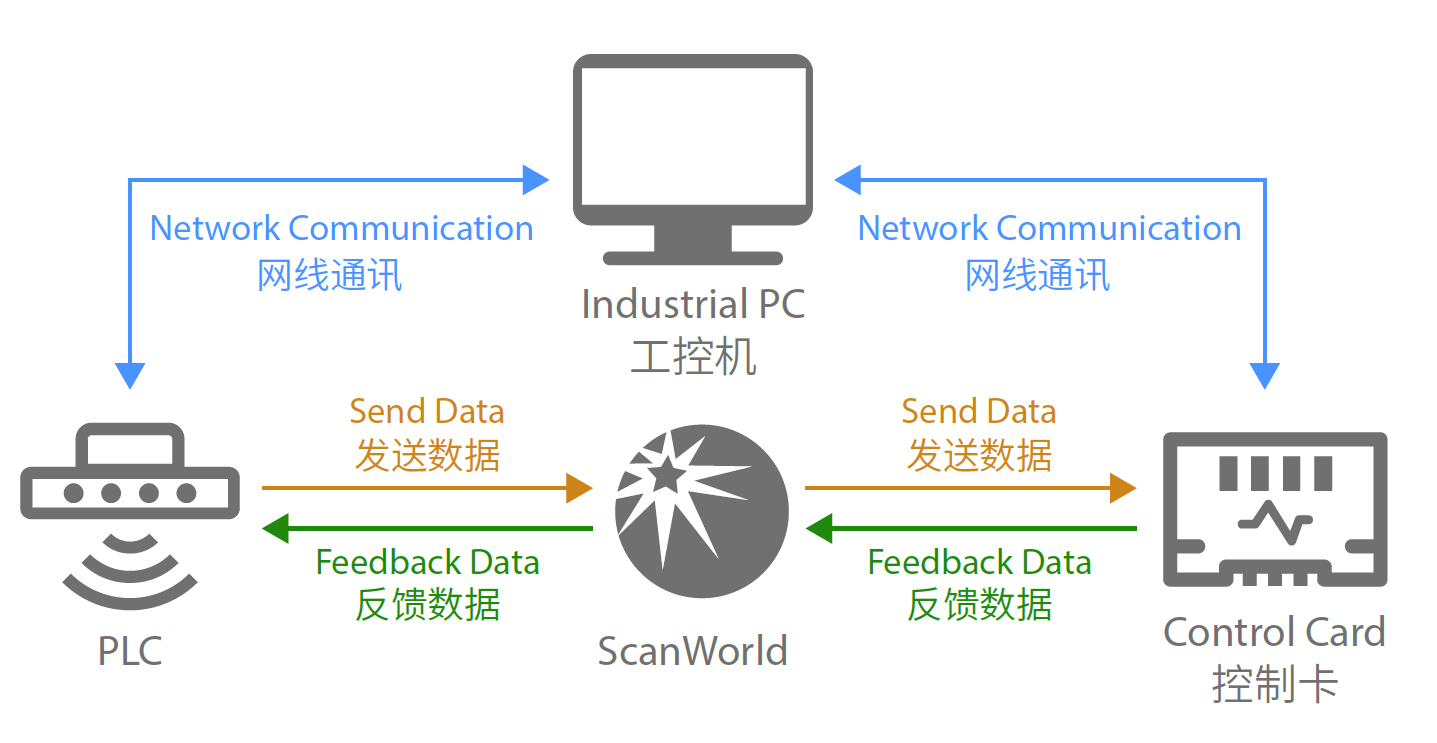

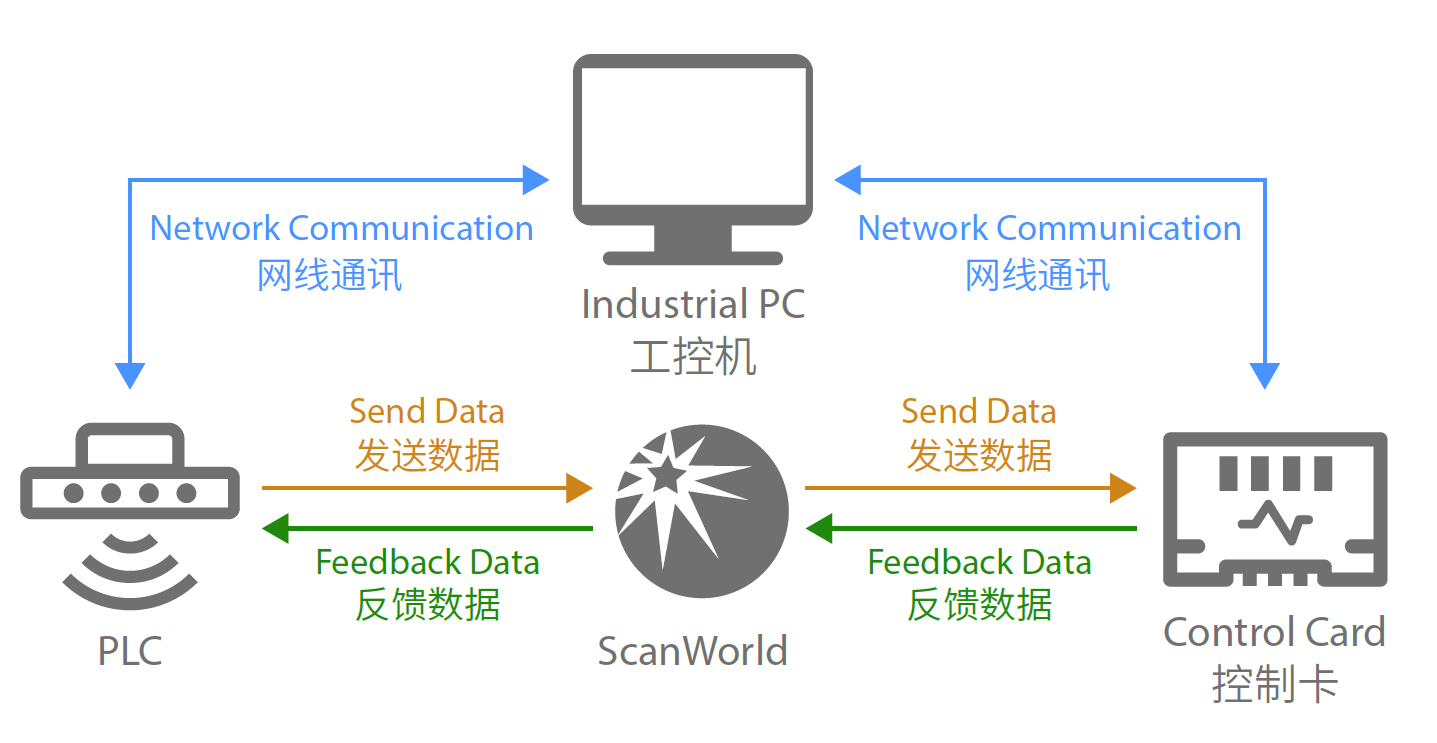

TCP Marking Function

Supports seamless communication with industrial controllers such as PLCS via standard TCP/IP protocols. Users can directly send instructions to the laser marking software (ScanWorld) via the network to trigger preset marking tasks in real time without the need for physical signal interaction.

Four-Axis Synchronizing Motion

It is equipped with a galvanometer (high-speed scanning of XY axes) and a servo platform (precise movement of XY axes) for coordinated control. Through real-time dynamic compensation and trajectory synchronization of four axes, it achieves ultra-large format and high-precision graphic marking (such as curved surface workpieces and full-plate plates).

Compatibility of RTC5/RTC6 Control Card

Fully compatible and supportive of the industry-leading RTC5 series laser control cards, it provides stable and reliable control signal output to ensure high-quality laser processing results.

Four-Axis Flying Machining

Based on four-axis collaborative control technology, the system intelligently divides large-scale cutting patterns into zones. After the galvanometer completes the cutting in the current area, the servo platform seamlessly moves to the next area. Through real-time trajectory compensation and dynamic splicing algorithms, it realizes large-format traceless cutting of materials such as FPC (flexible circuit Board). This capability extends 3D laser scanning software performance.

2.5D Laser Drilling

Breaking through the limitations of traditional two-dimensional planes, it supports the precise drilling processing of shallow three-dimensional (2.5D) features by using galvanometer systems. Provide non-contact and highly efficient micro-hole processing solutions.

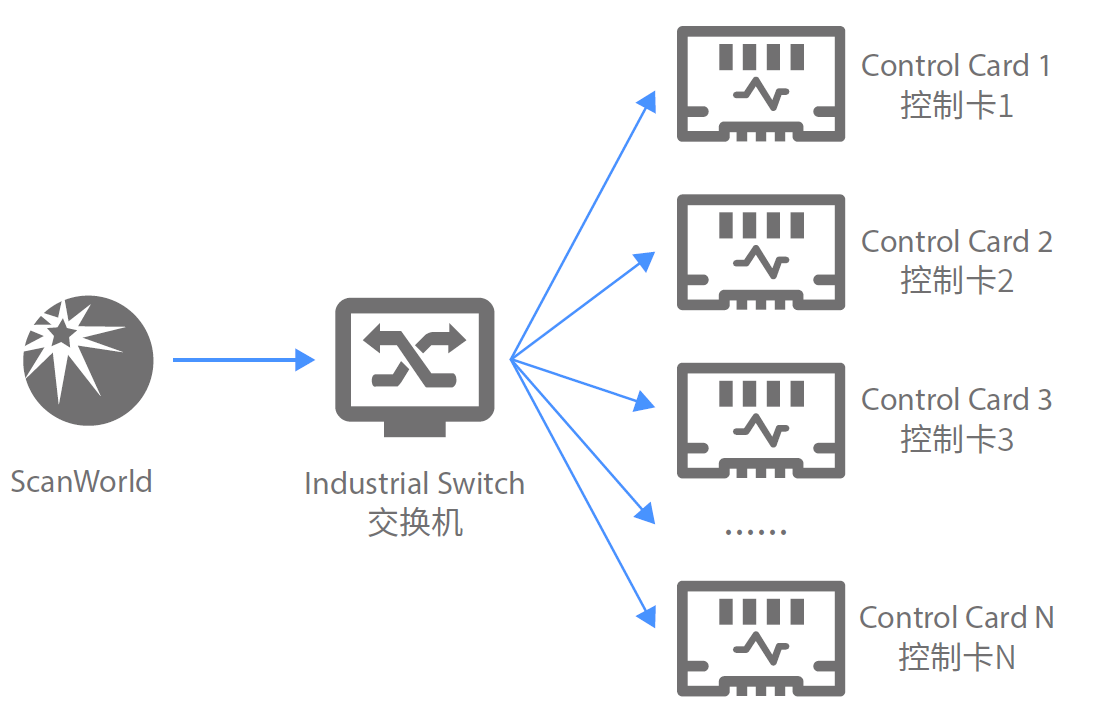

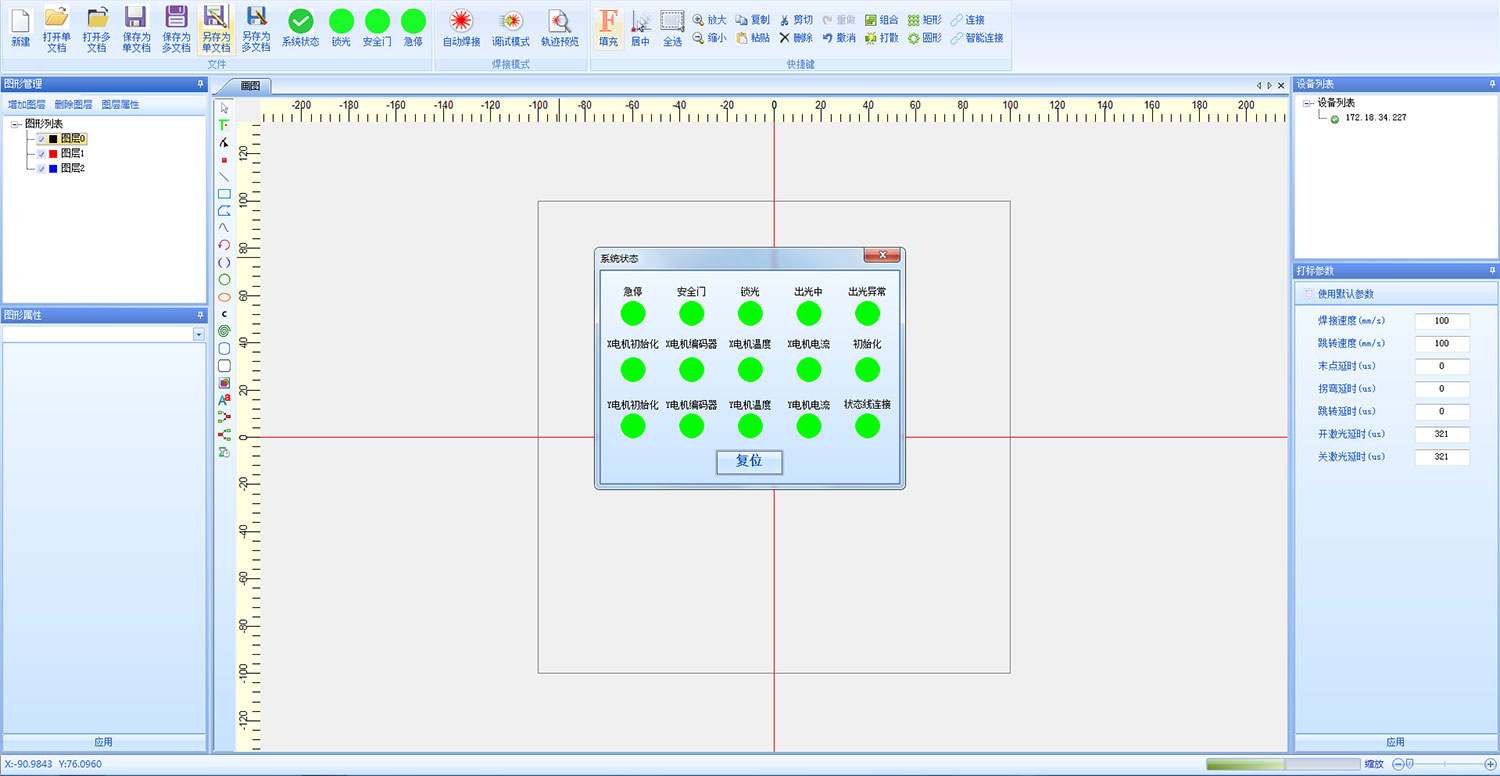

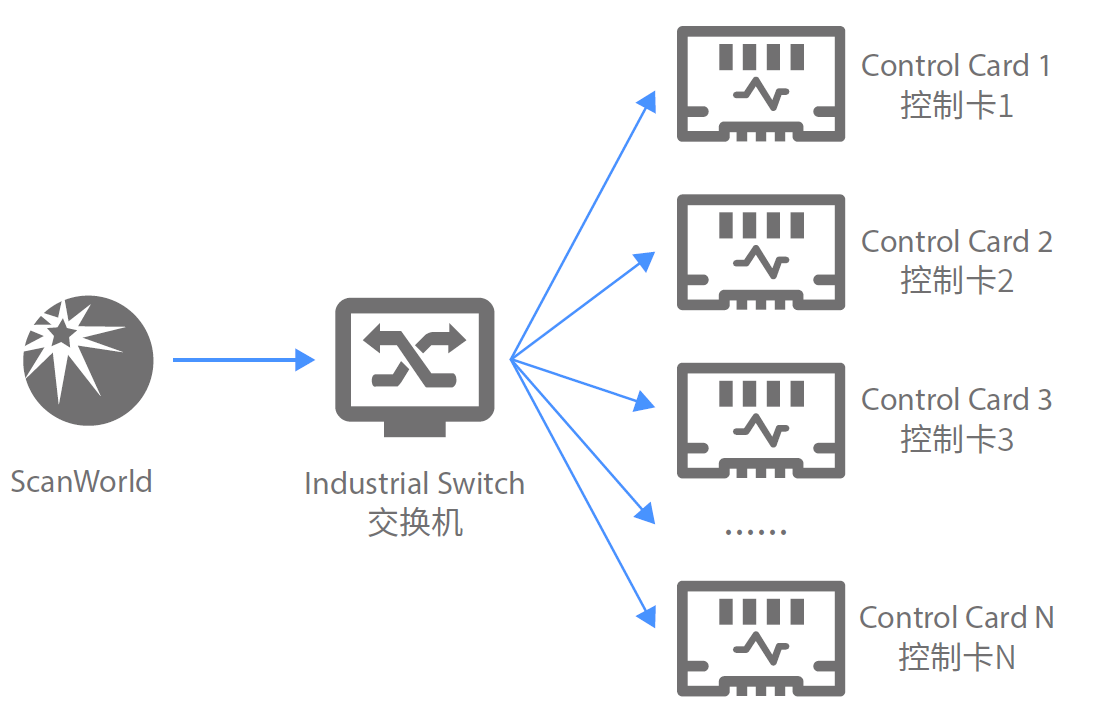

Multi-Card Marking Function

Visual Positioning Function

The visual positioning marking function adopts the deep integration technology of machine vision and laser processing. It captures the position of the workpiece in real time through a high-resolution industrial camera and intelligently compensates for positioning deviations, completely solving the problem of marking offset caused by manual placement errors.

Ultra-High-Speed Dotted Line Processing

In response to the special demands of the photovoltaic industry such as silicon wafer scribbling, an ultra-high-speed dotted line processing algorithm has been optimized and developed. Ensure precise and uniform dotted line trajectory processing at extremely high speeds to meet the strict process requirements of the industry.

Offline Marking

Configure a dedicated SD card storage expansion module. Support pre-downloading processing tasks (up to 16 documents) to the SD card. The system can be triggered by external I/O signals and independently perform stored processing tasks without being connected to the upper computer PC, thereby enhancing system reliability and production line flexibility.

Flying Marking

Supports two-axis (X/Y) and three-axis (X/Y/Z) flying marking modes.

Dynamic marking of objects on the conveyor belt is carried out by obtaining the speed changes of the coding wheel.

It is capable of intermittently typing characters and patterns while the object is moving.

On the production line where workpieces move continuously, real-time position tracking and dynamic laser processing are achieved to ensure the accuracy of the marked positions.

Tab cutting is a special marking technology evolved from the flying marking function. Unlike flying marking, tab cutting can only mark lines and not characters or graphic files.

Rotary Marking

Rotary marking technology adopts servo motor control and real-time trajectory compensation algorithm to achieve continuous dynamic processing of cylinders. Breaking through the traditional intermittent mode of "rotation - stop - marking", high-precision marking is completed during the uniform rotation of the workpiece, increasing production efficiency by 300% and completely eliminating seam errors.

Big Data Marking

The big data marking function is an ideal solution for handling complex graphics and application scenarios with huge amounts of data. It has completely resolved the performance bottleneck caused by large files, providing users with an efficient, stable and worry-free big data laser processing experience. It is a key productivity tool for enhancing production capacity and ensuring continuous production.

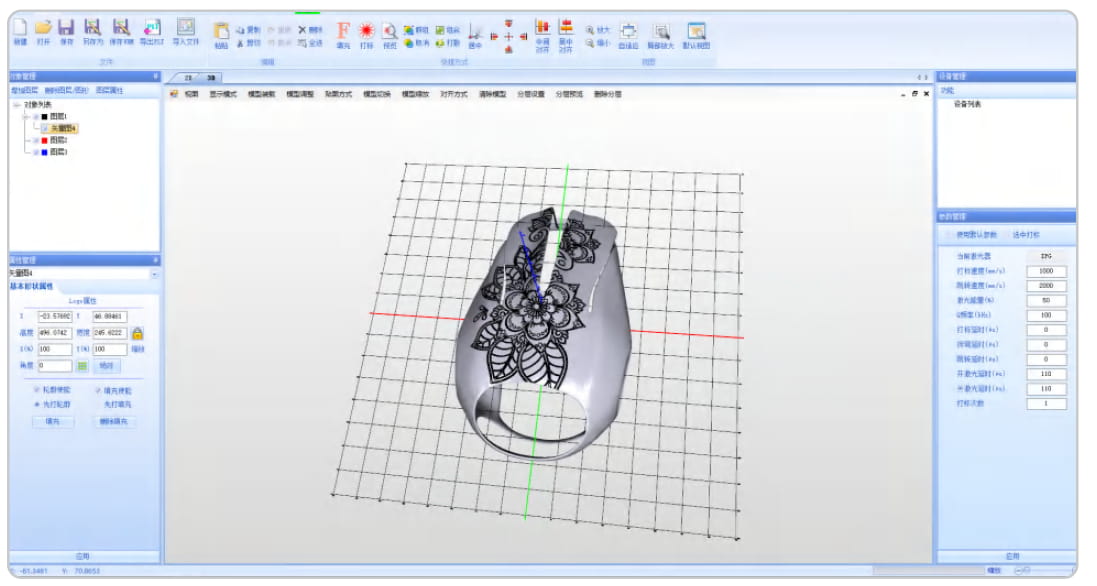

Layered Processing

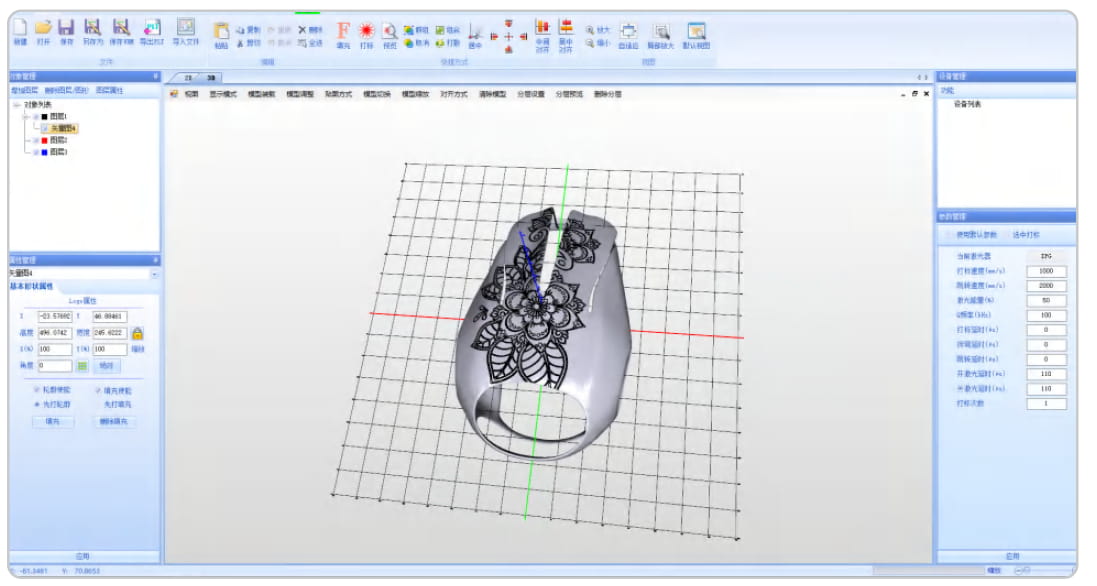

By intelligently slicing 3D models into layers, ScanWorld combines the power of 3D laser scanning software with engraving software functions. This ensures uniform depth processing on complex surfaces, overcoming the limitations of traditional 2D systems.

3D Large-Format Marking

Combined with three-dimensional dynamic focusing technology. Supports high-precision and high-consistency laser marking and engraving on complex three-dimensional curved surfaces with height differences or large-sized planes.

Vector Graphic Marking

The vector graphic marking function provides professional engineering-grade CAD/CAM data processing capabilities, supporting direct import and high-precision restoration of industrial standard vector formats such as PLT and DXF, achieving contour marking and cutting processing with micron-level accuracy, and meeting the strict requirements of the precision manufacturing field for geometric accuracy and repeat positioning.

Bitmap Marking

The bitmap marking function offers a professional-level image-to-laser processing solution, supporting direct import and intelligent processing of mainstream image formats (such as JPG, PNG, etc.). Through advanced gray-scale mapping algorithms, it precisely converts digital images into laser processing instructions, achieving surface marking with photo-level visual effects.

SUPPORT SERVICES

ScannerOptics provides prompt customer support for Scan World and regularly releases software updates on the official website.

HARDWARE REQUIREMENTS

| The installation and use of this software require that the computer should have at least the following software and hardware configurations |

| Operating System | Windows2000 / Windows XP / Windows 7(64 Bit() .NET4.0 and above) |

| CPU | Celeron 2G or above |

| Memory | At least 512 memory is required. If you need to handle large garphic files, it is recommended to have more than G4B of memory |

| Graphics Card | If the 3D function is used, a powerful independent garphics card is required for graphic processing |

| Hard Disk | At least 500M of available space is required. It is recommended to reserve more available space |

zh-CN

zh-CN

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt